Ball mill is a key piece of equipment for crushing materials after they are crushed. It can grind various ores and other grindable materials dry or wet.

Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal beneficiation, glass and ceramics and other production industries.

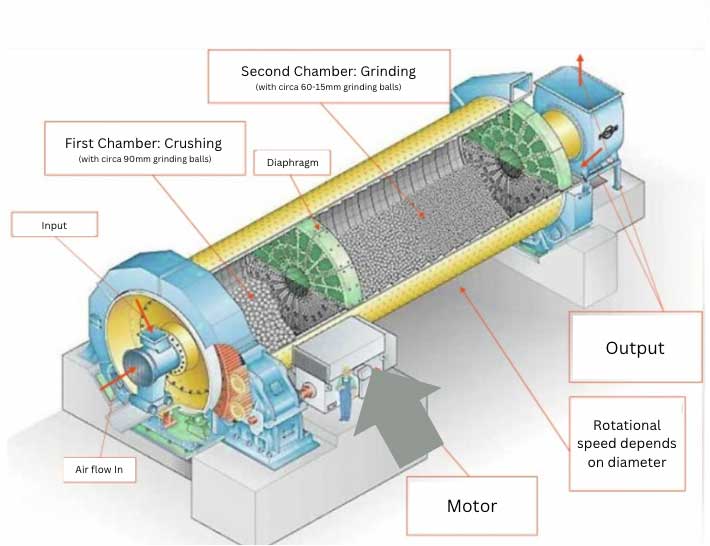

The structure of the ball mill is mainly composed of the feeding part, the discharging part, the rotating part, the transmission part (reducer, small transmission gear, motor, electronic control) and other parts. Among them, the hollow shaft is made of cast steel, the inner lining is removable, the rotating large gear is made of cast gear hobbing, and the cylinder is inlaid with a wear-resistant lining.

The traditional ball mill uses sliding bearings, and the friction coefficient of the main bearing is 0.008, which causes a high-temperature rise during operation and rapid aging of the lubricating oil, so the lubricating oil must be replaced every six months. In comparison, the new energy-saving ball mill uses rolling bearings, and the friction coefficient is only 0.0025, which is only 1/3.2 of the friction coefficient of sliding bearings. This greatly reduces the power consumption required to overcome friction resistance, which is only 1/3.2 of the sliding bearing ball mill. The new ball mill uses grease lubrication, which is added once a week or month and replaced once a year, which can save more than 80% of lubricating oil in total. In addition, the main bearing does not need cooling water cooling, which can save tens of thousands of tons of water every year and also reduces the power consumption of the oil station by eliminating the lubricating oil station.

1. According to Structure and Application Field: overflow ball mill, aluminum ash selection ball mill, grid ball mill, dry ball mill, small ball mill, ceramic ball mill, cement ball mill, etc.

2. According to the Shape of the Cylinder: short cylinder ball mill, the ratio of cylinder length to diameter is 1-2; Guan ball mill, the ratio of cylinder length to diameter is 2-7; conical ball mill, the length-to-diameter ratio is 0.25-1.0.

3. According to the Operation Mode: intermittent ball mill and continuous ball mill.

1. Wide Range of Materials

Can process more than 100 different mineral raw materials and can show excellent grinding effects, whether dry or wet grinding.

2. Large Crushing Ratio

Compared with other grinding equipment, it can grind materials to finer particle sizes.

3. Strong Production Capacity

By adjusting the discharge port, materials with different fineness requirements can be ground to meet different production needs.

4. Easy Maintenance

Made of wear-resistant materials, with a long service life and a relatively simple maintenance process, it saves enterprises a lot of time and money.

Ⅰ. Energy Saving and Consumption Reduction

1. Low Friction Power Consumption: The friction coefficient of rolling bearings is about 0.0025, which is much smaller than the 0.008 of sliding bearings. The corresponding sliding bearing ball mill needs to overcome the friction resistance. The power consumption is 3.2 times that of rolling bearing energy-saving ball mills, which can significantly reduce the energy consumption of ball mills. Generally, small ball mills can save 30%~35% of electricity, medium-sized ball mills can save 15%~20% of electricity, and large ball mills can save 10%~20% of electricity.

2. Save Lubricating oil: Rolling bearings are lubricated with grease, which is added once a week or month and replaced once a year. The cumulative lubricating oil can be saved by more than 80%, and the electricity consumption of lubricating oil stations and oil stations can also be saved.

3. No Need for Cooling Water: The main bearing of the rolling bearing does not need cooling water to cool, which can save a lot of water resources every year. For example, a large ball mill can save tens of thousands of tons of water every year.

Ⅱ. Easy Maintenance

1. Simple Maintenance Process: Rolling bearings do not require Babbitt alloy materials. The complex and technically demanding maintenance processes, such as smelting, casting and scraping of materials, greatly reduce the maintenance volume.

2. Long service life: Under normal circumstances, the service life of rolling bearings can reach more than 10 years, while the failure rate of sliding bearings is high, the requirements for lubricating oil, cooling water, pressure, etc., are high, and maintenance is difficult.

Ⅲ. Good Operating Performance

1. Good Starting Performance: The starting performance of rolling bearings is better than that of sliding bearings, which can reduce the starting current. For example, the energy-saving bearing edge transmission ball mill can reduce the starting current by 50%.

2. Good Concentricity: Rolling bearings have an automatic self-aligning function, and the concentricity deviation is within the allowable range, which can ensure the normal operation of the ball mill, improve the problems of insufficient concentricity and unstable operation of the ball mill, and reduce the wear on the hollow shaft.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

The grinding medium and material are brought to a certain height by the rotating cylinder so that they produce extrusion, impact and stripping between each other to grind the material. The material is loaded into the cylinder through the hollow shaft at the feed end of the mill. When the cylinder rotates, the grinding body is attached to the cylinder lining due to inertia and centrifugal force and is carried away by the cylinder. After reaching a certain height, it is thrown down due to gravity, and the falling grinding body crushes the material in the cylinder. After the material is coarsely ground in the first bin, it enters the second bin through a single-layer partition plate for further grinding, and the powder is discharged through the discharge grate plate.

Ball Mill Technical Parameters | |||||||

Model | Rotary Speed | Ball Load | Input Size(mm) | Output Size(mm) | Capacity | Power | Weight |

φ900x1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

φ900x3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

φ1200x2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

φ1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

φ1200x4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

φ1500x3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 45327 | 75 | 19.5 |

φ1500 x4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

φ1500x5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

φ1830x3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

φ1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

φ1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

φ1830x7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

φ2100x3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

φ2100 x4500 | 23.7 | 24 | <25 | 0.074-0.4 | 15919 | 245 | 56 |

φ2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

φ2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 16681 | 280 | 54.5 |

φ2200x6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 62.5 |

φ2200x7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 64.8 |

φ2200x7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 58 |

φ2400x3000 | 21 | 23 | <25 | 0.074-0.4 | 18445 | 245 | 72 |

φ2400x4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 95 |

φ2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 102 |

φ2700x4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 149 |

φ3200x4500 | 18 | 65 | <25 | 0.074-0.4 | Customizable | 630 | 169 |

φ3600x4500 | 17 | 90 | <25 | 0.074-0,4 | Customizable | 850 | 198 |

φ3600x6000 | 17 | 110 | <25 | 0.074-0.4 | Customizable | 1250 | 260 |

φ3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 230 |

φ4000x5000 | 16.9 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 242 |

φ4000x6000 | 16.9 | 146 | <25 | 0.074-0.4 | 65-248 | 1600 | 249 |

φ4000x6700 | 16.9 | 149 | <25 | 0.074-0.4 | 75-252 | 1800 | 280 |

φ4500×6400 | 15.6 | 172 | <25 | 0.074-0,4 | 84-306 | 2000 | 320 |

φ5030×6400 | 14.4 | 216 | <25 | 0.074-0.4 | 98-386 | 2500 | 403 |

φ5030x8300 | 14.4 | 266 | <25 | 0.074-0.4 | 118-500 | 3300 | 525 |

φ5500×8500 | 13.8 | 338 | <25 | 0.074-0.4 | 148-615 | 4500 | 525 |