Raymond Mill, produced by Anshun, adopts the advanced structure of similar products at home and abroad and is updated and improved based on Raymond Mill in the same industry. The equipment has lower power, lower power consumption, a smaller footprint, and a smaller one-time investment than the ball mill. The grinding roller is tightly pressed on the grinding ring under the action of centrifugal force, so when the grinding roller and grinding ring are worn to a certain thickness, it does not affect the output and fineness of the finished product. The grinding ring, roller, and other wearing parts have a long service life. The machine's airflow is circulated in the fan-mill shell-cyclone separator-fan, which has less dust, a clean operation workshop, and a pollution-free environment. The finished product particle size can be adjusted arbitrarily within the range of 60-400 mesh according to needs, and some materials can reach 600 mesh.

Raymond mill, also known as Raymond mill, is a new type of equipment that can replace ball mills. It adopts closed-loop high-fine powder-making equipment. Raymond mill is widely used in metallurgy, building materials, chemical industry, mining, and other fields for grinding industrial and mining products. It is suitable for processing various non-flammable and explosive minerals with Mohs hardness below level 7 and humidity below 6%, such as gypsum, talc, calcite, limestone, marble, potassium feldspar, barite, dolomite, granite, kaolin, penrun clay, medical stone, bauxite, red iron oxide, iron ore, etc. The finished product fineness is between 613 and 440 microns (0.613 mm-0.044 mm). Through the joint action of the analyzer and the fan, it can meet the use requirements of different users.

Because the Raymond mill has fine powder output and the hourly output is not very high, it is often called a small Raymond mill. So, how much does this small Raymond mill cost? Many customers are concerned about the price. Henan Anshun Machinery Factory produces eight types of Raymond mills. Each model has different configurations, sizes, outputs, weights, etc. Therefore, the prices of each model are different. There are small Raymond mills with a price of more than 10,000 US dollars and large Raymond mills with a price of hundreds of thousands of US dollars.

If you want a specific quote for a small Raymond mill, please contact the manufacturer directly for consultation. Contact WhatsApp: 8615838136988, Email: info@ascrusher.com

1. The finished product fineness of Raymond Mill is uniform, and the screening rate is 99%, which is difficult for other grinding equipment to have.

2. The Raymond mill's electrical system adopts centralized control, and the grinding workshop can basically realize unmanned operation and is easy to maintain.

3. The important parts of the Raymond mill are made of high-quality steel, and the wear-resistant parts are made of high-performance wear-resistant materials. The whole machine is highly wear-resistant and reliable.

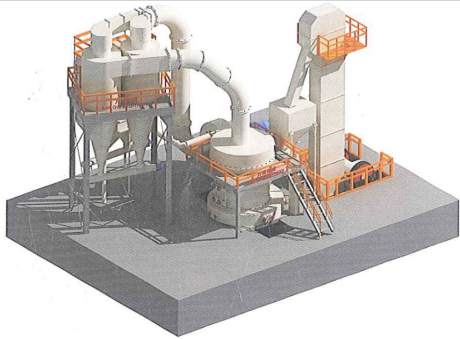

4. The Raymond mill has a three-dimensional structure, small footprint, strong completeness, and an independent production system from block materials to finished powder materials

5. The Raymond mill's transmission device adopts a closed gear box and pulley, which ensures stable transmission and reliable operation.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

When the Raymond mill works, the crushed material is added to the machine from the feed hopper on the side of the machine cover. Relying on the grinding roller device suspended on the main machine plum blossom frame, it rotates around the vertical axis. Due to the centrifugal force during rotation, the grinding roller swings outward and presses against the grinding ring so that the shovel blade scoops up the material and sends it between the grinding roller and the grinding ring. The purpose of crushing the material is achieved by rolling the grinding roller.

Model Parameters | 3R6010 | 3R7616 | 3R7816 | 3R8817 | 3or4R9716 | 3or4R9918 | 5R4123 | 6R4830 |

Maximum Feed Size | 5-8mm | 15mm | 20mm | 22mm | 25mm | 25mm | 30mm | 35mm |

Finished Particle Size | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 |

Capacity(t/d) | 1-4 | 2-6 | 2-8 | 3-12 | 4-15 | 5-20 | 6-40 | 10-50 |

Center Shaft Speed | 280 | 150 | 150 | 150 | 140 | 140 | 103 | 82 |

Roller Diameter(mm) | 150 | 260 | 270 | 300 | 320 | 310 | 410 | 480 |

Roller And Griding Ring Height(mm) | 100 | 160 | 160 | 170 | 160 | 180 | 230 | 300 |

Main Motor(Kw) | 6-7.5kw | 8-18.5kw | 8-22kw | 8-30kw | 4-37kw | 8-37kw | 4-75kw | 4-160kw |

Fan Motor(Kw) | 4-7.5kw | 4-18.5kw | 4-22kw | 4-30kw | 4-30kw | 4-37kw | 4-90kw | 4-160kw |

Motor Analyzer(Kw) | 6-1.1kw | 6-2.2kw | 6-2.2kw | 6-2.2kw | 4A-7.5kw | 6-7.5kw | 4B-11kw | 4B-22kw |

Installation Dimensions(m) | 3.34*2.161*3.246 | 4.65*3.30*4.5 | 4.60*3.40*4.80 | 5.00*4.50*5.20 | 8.50*5.80*8.00 | 7.50*5.80*9.00 | 10.00*11.00*7.00 | 10.00*11.00*9.00 |