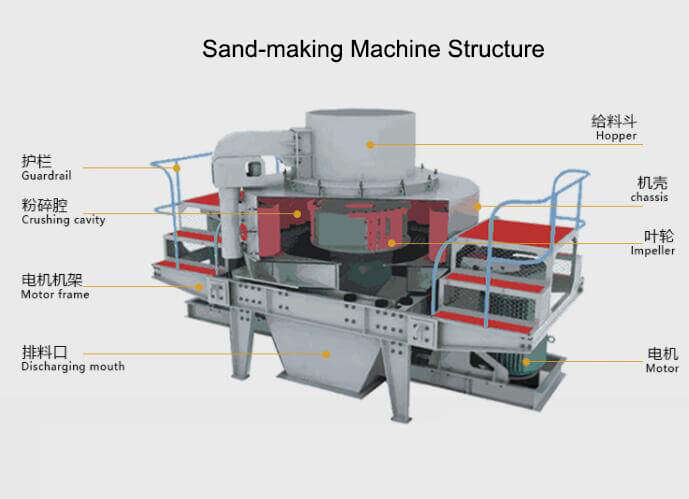

VSI6XG sand making machine adopts advanced manufacturing technology and innovative design, and is designed for efficient crushing and sand and gravel production. It can effectively process various ores and rocks, provide excellent sand and gravel quality, and is widely used in construction, highways, railways and other fields, providing reliable material support for engineering construction.

VSI6XG sand making machine is an efficient sand making machine, designed to meet the production needs of high-quality machine-made sand and aggregates. It adopts advanced technology and innovative design and has the following main features:

High efficiency and energy savings: The optimized rotor structure and deep cavity design improve production efficiency and reduce energy consumption.

Easy maintenance: The equipment's simple design makes it easy to operate and maintain and reduces downtime.

Strong durability: The use of high-quality, wear-resistant materials prolongs the service life of the equipment.

Environmental performance: Equipped with environmental protection devices, it reduces dust and noise pollution during production.

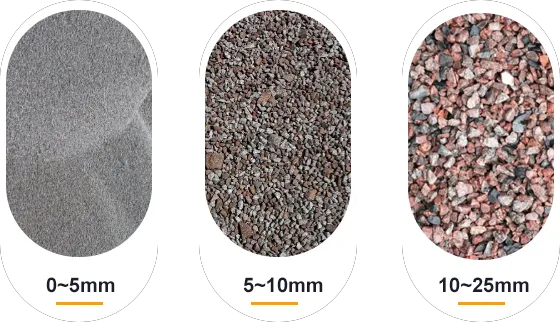

Versatile application: Suitable for various hardness materials and can produce sand and gravel products of different particle sizes.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

During the production process of VSI6XG sand making machine, firstly, bulk materials are evenly fed into the jaw crusher through the vibrating feeder for primary crushing, then the materials are conveyed to the impact crusher for medium and fine crushing, and finally enter the sand making machine for sand making and shaping. The finished products are screened and graded by the vibrating screen. The materials that do not meet the standards will be returned to the sand making machine for re-crushing until the required particle size is reached.

Model | VSI6X13100G | VSI6X1380G | VSI6X1263G | VSI6X1150G | |

Throughput t/h | Crushing | 783-839 | 601-643 | 454-486 | 344-368 |

Shaping | 940-1309 | 721-1004 | 545-758 | 413-575 | |

Max Feed Size(mm) | Crushing | ≤50 | ≤50 | ≤50 | ≤45 |

Shaping | ≤60 | ≤60 | ≤60 | ≤55 | |

Rotational Speed (r/min) | 800-1100 | 800-1100 | 900-1200 | 1000-1300 | |

Dual Motor Power (kw) | 1000 | 800 | 630 | 500 | |

Dimension(LxWxH)(mm) | 7900×2980×4150 | 7900×2980×4150 | 7440×2980×4100 | 7440×2750×3880 | |

Weight(t) | Rock For Rock | 33 | 32.5 | 29 | 24 |

Stone For Iron | 36.5 | 36 | 32 | 26.5 | |

Power Source | Voltage(V):AC380、400、415、440、480 Frequency(Hz):50、60 | ||||

Thin Oil Lubrication Station | L/min | 4-16 | |||

Pump Motor Power (kW) | 0.75 | ||||

Heater Power (kW) | 4 | ||||

Safety Protection | Automatic shutdown is when there is no oil flow; air cooling is for cooling; the heating system starts in winter. | ||||