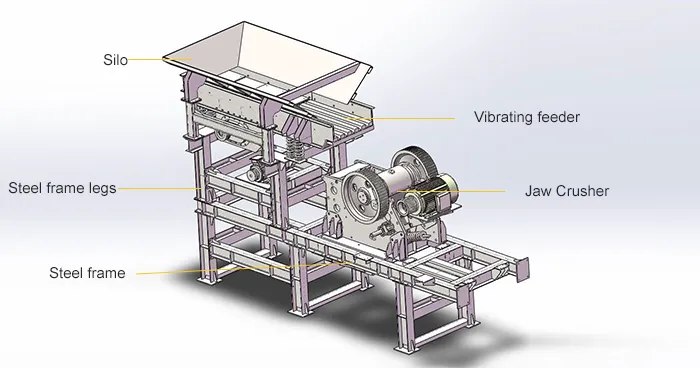

Modular Stone Jaw Crushing Plant in the mining industry is an efficient and stable crushing equipment designed for ore crushing and stone processing. The equipment integrates crushing, screening and conveying, adopts a modular structure and a sturdy frame design to ensure long-term stable operation under high-load working conditions. As the core crushing unit, the jaw crusher crushes large ore materials into the required particle size through its powerful compression and crushing action, providing an ideal material particle size for subsequent processes. The jaw crusher frame plant adopts an open or closed design to meet the operating requirements of different mining sites.

1. Strong structure, suitable for heavy load conditions

The jaw crusher frame plant adopts high-strength steel structure main frame and modular frame design, with excellent bearing capacity and impact resistance. It is suitable for primary crushing operations of various types of ores, including continuous operations in high-hardness rocks and complex terrain environments.

2. Efficient crushing capability

Equipped with heavy-duty jaw crusher, it has large crushing ratio, large feed size and adjustable discharge size. The crushing chamber is deep and has no dead zone, and the material passing rate is high, which can significantly improve the processing capacity of the entire line and meet the needs of large-scale ore coarse crushing.

3. Modular combination, easy installation

The use of standardized modular units facilitates quick assembly and disassembly, and the screening and conveying systems can be flexibly configured according to on-site requirements, significantly shortening the construction period and reducing civil engineering costs.

4. Stable operation and easy maintenance

The whole plant system has a reasonable layout, and key components are easy to repair and replace. Combined with the centralized lubrication system and hydraulic adjustment mechanism, it effectively extends the life of the equipment and reduces maintenance intensity.

5. Intelligent control system

Equipped with advanced PLC automation control platform and remote monitoring module, it can realize real-time monitoring and fault warning of key data such as crushing parameters, load status, lubrication system, etc., to ensure safe and stable operation of the equipment.

6. Strong scalability

The frame plant can expand the secondary and tertiary crushing or screening modules according to the process flow to meet the requirements of different particle size grading and production capacity. It has strong adaptability and supports later upgrades and renovations.

7. High environmental adaptability

Optional environmentally friendly configurations such as closed structure, spray dust removal system and belt dust suppression hood can effectively control dust and noise emissions and meet green mine construction standards.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

As a key equipment in the primary crushing process of mines, the core principle of the jaw crusher frame plant is based on the mechanical compression and crushing of ore by the jaw crusher. The material enters the crushing chamber from the upper feed port. Driven by the eccentric shaft, the movable jaw plate swings periodically toward the fixed jaw plate around the fixed axis to achieve repeated extrusion, splitting and bending crushing of the material. When the material particle size is crushed to a size smaller than the set value of the discharge port, it is discharged from the bottom under the action of gravity, completing the crushing process.

Modular Stone Jaw Crushing Plant Technical Parameters | |||||||

Model | Vibrating feeder | Jaw crusher | Vibrating screen | Belt conveyor | Capacity | Power system | Chasis |

SKPZ46-1548 | ZSW850×3000 | PE400×600 | 3YK1548 | B650×10×3sets | 15-60tph | Electrical Control or Generator | Tracked mobile,wheel |

SKPZ57-1848 | ZSW960×3800 | PE500×750 | 4YK1848 | B650×10×4sets | 50-100tph | ||