Crawler screening mobile crushing plant is a highly efficient screening and crushing equipment, which can be driven directly to the site, with convenient transfer operation, high screening efficiency and large output. It is particularly suitable for operations in complex terrain areas such as narrow sites and urban demolition, especially for construction waste treatment, and can also be used for mineral and hard rock screening, sand and gravel aggregate production, which can fully meet customers' mobile screening requirements.

The vibrating screen has a large effective screening area and the screening angle can be hydraulically adjusted

The vibrating screen can be hydraulically raised and lowered, leaving enough space for maintenance and screen replacement

Optional multiple power drives, strong flexibility and maneuverability, no need for supporting legs or fixed foundation when working

Super strong screening ability, the maximum material can reach 800mm

Fuel efficiency increased by 25%

Dual-use, more stable, more productive and safer

1.Diesel engine with excellent performance

Cummins diesel engines have low fuel consumption and low noise. They are stable, reliable, economical and environmentally friendly power sources. The engines are equipped with military low-temperature preheating and starting devices, which can conquer low-temperature environments as low as -40°C.

2.Mobility and flexibility

It can quickly enter the construction site, saving time and transportation costs. It can be transferred on rugged and harsh terrain and can be flexibly placed according to the terrain and site, providing more flexible space for the reasonable arrangement of crushing and screening processes.

3.Hydraulic drive, easy to adjust

It adopts advanced hydraulic drive, which can quickly realize operations such as belt lifting and lowering and discharge opening adjustment.

4. Intelligent control

The whole vehicle adopts PLC control system to monitor the operation status of the equipment in real time, handle various situations in the work in time, and effectively protect the normal operation of the whole machine. The operation control system has a friendly interface, simple operation and convenient maintenance.

5. Effectively reduce costs

The equipment is equipped with a vibrating feeder, a grate structure at the inlet end, and a two-layer screen design, which can pre-screen the material and effectively remove the dirt in the material. The fine material directly enters the main belt conveyor, which can reduce the load of the main machine, improve the material quality, make the processing more reasonable, and effectively reduce costs.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

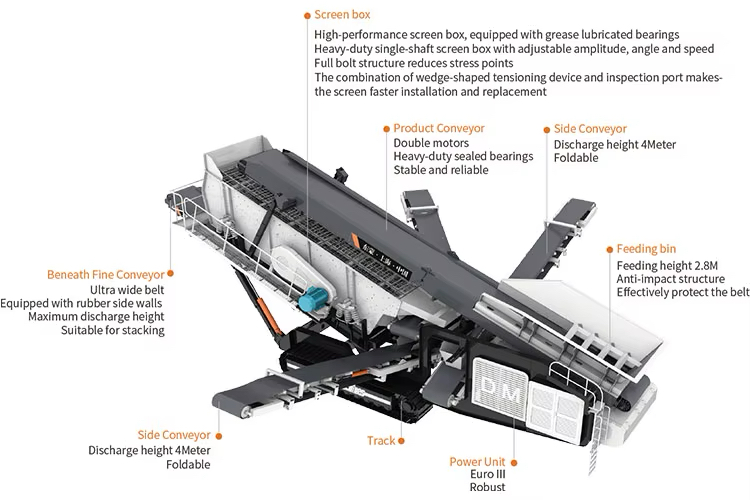

The core working mechanism of the crawler screening plant is based on a multi-layer vibrating screening system. After the material is input through the feed hopper, it is sent to the screening unit through the main conveying system. Driven by the vibrator, the material moves in a graded manner on the screen surface. Particles of different sizes are separated in turn according to the size of the screen holes and output to the designated stockpiling area through belts at various levels.

Crawler Screening Plant Technical Parameters | ||

Model | TS1860 | TS2160 |

Screen Box | ||

Dimensions (Mm) | 1800x6000 Three Layers | 2100x6000 Three Layers |

Feed Size | ≤200mm | 6200mm |

Screen Size | 5-100mm | 5-100mm |

Drive Mode | Hydraulic Motor Drive | Hydraulic Motor Drive |

Frame | ||

Hydraulic Crawler Chassis | 40t | 40t |

Boat-Shaped Frame | q345b Welding | q345b Welding |

Feeding Belt Conveyor | ||

Specification | b1000*11.8m | b1000*11.8m |

Drive Mode | Hydraulic Motor Drive | Hydraulic Motor Drive |

Endless Polyester Canvas Belt | Ep-200-b1000×4(4.5+1.5) | Ep-200-b1000×4(4.5+1.5) |

One Layer Belt Conveyor | ||

Specification | b650*5.9m | b650*5.9m |

Discharge Height | 2.8 m | 2.8 m |

Drive Mode | Hydraulic Motor Drive | Hydraulic Motor Drive |

Endless Polyester Canvas Belt | Ep-200-b1000×4(4.5+1.5) | Ep-200-b1000×4(4.5+1.5) |

Two-Layer Belt Conveyor | ||

Specification | b650*7.5m | b650*7.5m |

Discharge Height | 3.5 m | 3.5 m |

Drive Mode | Hydraulic Motor Drive | Hydraulic Motor Drive |

Three-Layer Belt Conveyor | ||

Specification | b650*7.5m | b650*7.5m |

Discharge Height | 3.5 m | 3.5 m |

Drive Mode | Hydraulic Motor Drive | Hydraulic Motor Drive |

Endless Polyester Canvas Belt | Ep-200-b650×4(4.5+1.5) | Ep-200-b650×4(4.5+1.5) |

Under-Screen Belt Conveyor | ||

Specification | b1000*8.5m | b1000*8.5m |

Discharge Height | 3.6 m | 3.6 m |

Drive Mode | Hydraulic Motor Drive | Hydraulic Motor Drive |

Endless Polyester Canvas Belt | Ep-200-b1000×4(4.5+1.5) | Ep-200-b1000×4(4.5+1.5) |

Powertrain | ||

Engine + Transfer Case + Pump | 154kw Engine | 154kw Engine |

Electrical System | ||

Electric Control Cabinet | The Screen Displays Engine Operating Parameters Monitoring, Crawler Walking, And | The Screen Displays Engine Operating Parameters Monitoring, Crawler Walking, And |

Each Belt Conveyor Can Be Operated Remotely | Each Belt Conveyor Can Be Operated Remotely | |

Hydraulic System | ||

Various Types Of Cylinders | Belt Conveyor Folding, Vibrating Screen Lifting | Belt Conveyor Folding, Vibrating Screen Lifting |

Hydraulic Pumps, Valves, Accessories | Load Sensitive, Electro-Hydraulic Proportional Valve Group | Load Sensitive, Electro-Hydraulic Proportional Valve Group |