PLF vertical compound crusher is an efficient sand making equipment, also known as vertical shaft sand making machine. The vertical compound crusher is a new type of equipment developed by optimizing the design of key technical parameters based on the technology of similar crushers at home and abroad. It has excellent performance in the fields of fine crushing and coarse grinding.

The primary application scenario of the PLF vertical compound crusher is the processing of medium-sized cement raw materials and clinker. It provides an ideal fine crushing solution for the technological upgrading of cement plants and the construction of new cement production lines. Not only that, the vertical shaft sand making machine can also be widely used in the crushing operations of medium-hard ores such as iron ore, sandstone, gypsum, blast furnace slag, coal gangue, and lump coal.

The compound crusher has many significant advantages: large crushing ratio, which can efficiently break large materials into fine particles; low energy consumption, effectively reducing operating costs; smooth operation without severe vibration; simple structural design, easy operation and daily maintenance Maintenance can significantly reduce downtime and maintenance costs, thereby improving overall production efficiency and economic benefits.

1. Large Crushing Ratio

It can break larger particle-size materials into smaller particle-size finished products, reducing subsequent processing steps.

2. Low Energy Consumption

Compared with other similar crushers, under the same production capacity, energy consumption is lower, saving energy costs.

3. Smooth Operation

The equipment has low vibration and low noise when running, reducing the impact on the working environment and extending the service life of the equipment.

4. Simple Structure

The main components are reasonably laid out and easy to understand and operate, reducing maintenance difficulty and cost.

5. Easy to Operate and Maintain

Routine inspection and maintenance work is relatively easy, wearing parts are convenient to replace, and equipment downtime is shortened.

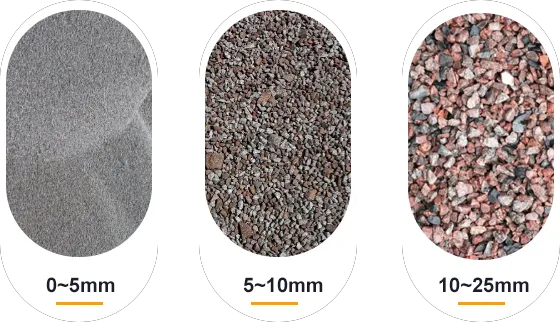

6. Product Particle Size is Uniform

The crushed materials have relatively consistent particle size, high packing density, cube shape, and minimal iron contamination, making them suitable for the production of high-quality building materials.

7. Less Affected by Moisture

The moisture content can reach about 8%, which has a better crushing effect on wet materials and is less prone to problems such as clogging.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

When the PLF vertical compound crusher is working, the material enters the equipment from the feed hopper, and is evenly distributed around the whirling crushing cavity through the distributor. Driven by the high-speed rotating impeller, the material is accelerated, and then hits the material lining in the vortex crushing cavity at high speed. At the same time, it also collides with the material emitted from the impeller channel. After many times of impact and friction, the finished sand with qualified particle size is discharged from the discharge port at the bottom of the equipment.

PLF Vertical Compound Crusher Technical Parameters | ||||||

Model | Input Size(mm) | Output Size(mm) | Capacity(t/h | Spindle Speeds(r/min) | Power(kw) | Overall Dimensions (mm) |

PFL-800 | <100 | <3-560-90% | 10-20 | 934 | 37 | 2100×1200×1700 |

PFL-1000 | <120 | <3-560-90% | 20-40 | 769 | 55 | 2600×1400×1900 |

PFL-1250 | <150 | <3-560-90% | 40-70 | 530 | 90 | 2800×1600×2100 |

PFL-1500 | <190 | <3-560-90% | 70-100 | 495 | 160 | 3100×1900×2200 |

PFL-1750 | <200 | <3-560-90% | 130-190 | 424 | 200 | 3710×2360×2390 |

PFL-2000 | <220 | <3-560-90% | 160-230 | 370 | 250 | 4100×2660×2620 |