Anshun Machinery's SRM series vertical mills are developed through continuous innovation and upgrade by our R&D team after fully drawing on advanced vertical mill technology at home and abroad. This new type of high-efficiency vertical mill has significant advantages, such as low investment and operating costs, excellent finished product quality, and convenient operation and maintenance. It is also energy-saving, environmentally friendly, and pollution-free, and meets the needs of modern industry. Its excellent performance and quality have been widely used in many industries, such as metallurgy, electric power, cement ash, industrial waste gas desulfurization, and comprehensive utilization of waste residue.

SRM vertical mills are highly flexible and provide multiple optional configurations and customized services to meet various industrial needs.

1. Static Powder Separator: simple structure, low energy consumption, and low maintenance cost. It is suitable for production with loose requirements on finished product particle size, small scale, and limited budget, such as rough processing of building materials, relying on natural sedimentation to separate materials, and screening large particles back to grinding.

2. Dynamic Powder Concentrator: It uses a high-speed rotating rotor to generate a strong centrifugal force field, finely classify materials, and accurately control particle size. It meets the requirements of the mid-to-high-end market for powder uniformity and fineness. Electronic materials, fine chemicals, and other industries often use it to ensure product quality. Stabilize.

3. Combined Powder Separator: This system integrates the advantages of dynamic and static powder separators, multi-stage classification, static coarse screening, and dynamic fine classification. It is suitable for large-scale high-precision production, such as large-scale cement production lines, considering high output and excellent grain control.

1. Site Adaptability Design: Customize the installation plan according to the size, layout, and environment of the customer's site. It can be reasonably arranged in small indoor or open spaces to facilitate equipment operation and maintenance and improve space utilization.

2. Customization of Material Properties: Customization for hardness, humidity, viscosity, corrosiveness, and other characteristics. Use wear-resistant grinding rollers for hard materials and optimize the pressure system; dry or adjust hot air parameters for wet materials; use corrosion-resistant parts for corrosive materials to ensure stable equipment operation.

3. Process Integration Customization: Integrate SRM mills with transportation, storage, dust removal, packaging, and other equipment to build an automated production line. According to customer product and process requirements, material flow is balanced, energy is matched, and control is coordinated to ensure efficient and stable production lines.

1. Low Investment Cost: It integrates grinding, drying, grading, and conveying. Its simple structure and compact layout can be arranged in the open air. Compared with traditional grinding equipment, the investment cost is significantly reduced.

2. The Transmission System has High Load-Bearing Capacity: Its transmission reducer adopts a new structure, which has a greater load-bearing capacity than traditional vertical mills and can better adapt to working requirements under different working conditions and ensure the stable operation of the equipment.

3. The Hydraulic Device is Easy to Maintain: The advanced hydraulic control system can automatically adjust the pressure according to material changes to maintain the best working condition of the mill. This reduces energy consumption and extends the service life of the roller sleeves and liners. The hydraulic device is very convenient for maintenance, which reduces the difficulty and cost of equipment maintenance.

4. Thin Oil Lubrication Operates Reliably: Equipped with the most advanced independent oil station and automatic protection system, it provides a reliable guarantee for the operation of the equipment, ensures the safety and stability of the device during operation, and reduces equipment failures caused by lubrication problems. Fault.

5. A Variety of Powder Selectors are Widely Applicable: The equipment can select powder selectors with different structures according to the requirements of different materials and fineness. The powder selector adopts frequency conversion speed regulation to make the particle size distribution more uniform and the fineness easier to adjust, which can meet various production needs and a wide range of applications.

6. The Electronic Control System has a High Degree of Automation: It is equipped with an advanced electronic control system that can realize PLC, centralized, and DCS control and can meet customers' diverse control needs. Automated control not only improves production efficiency but also reduces manual operations. Strength and turnover rate.

7. Energy Saving and Environmental Protection: The equipment operates with low noise. After dust removal, the emission concentration of the grinding products is lower than the national environmental protection requirements, which meets the requirements of modern industry for energy saving and environmental protection and helps enterprises achieve green production.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

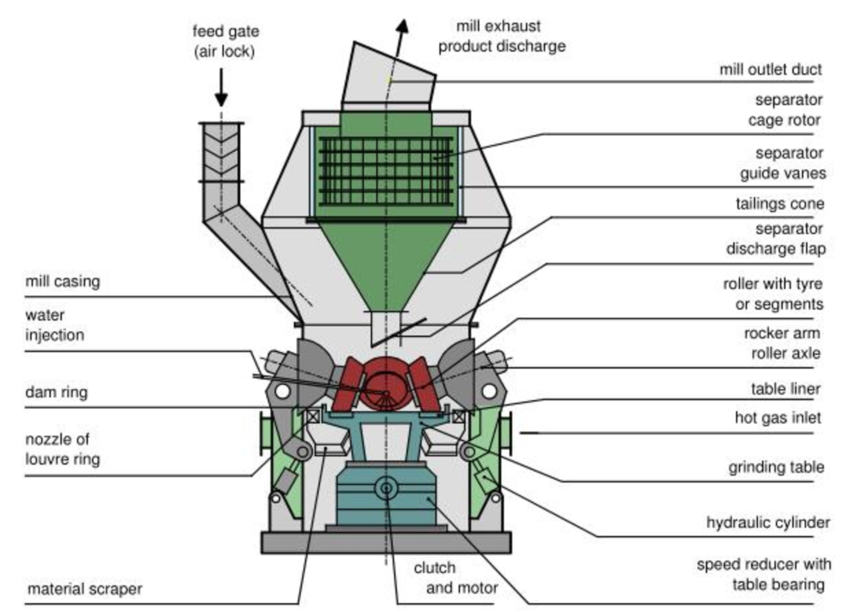

SRM vertical mill mainly consists of a grinding roller assembly, grinding disc assembly, hydraulic station, transmission arm assembly, powder separator, main reducer, electric motor, body, main reducer lubrication station, hydraulic station, and PLC electronic control cabinet composed of other parts. When working, the main motor drives the grinding plate to rotate through the reducer. At the same time, the hot air enters the vertical mill body from the air inlet. The material falls from the discharge port to the middle of the grinding plate. Under the action of centrifugal force, the material moves evenly from the middle to the edge of the grinding plate and passes through the grinding plate. When the grinding roller area is on the grinding machine, the grinding roller crushes it, and the large materials are directly crushed. The fine-grained materials are extruded to form a material bed for intergranular crushing. The crushed materials continue to move toward the edge of the grinding disc until they are taken away by the strong airflow at the air ring, and the larger particles fall back to the grinding disc to continue crushing. When the materials in the air flow pass through the upper separator, they are crushed on the rotor. Under the action of the blades, the coarse particles return to the grinding disc for grinding, and the qualified fine powder comes out of the grinding machine along with the airflow. The system's powder collector collects it. The collected powder is the product ground by the vertical mill. When the iron blocks and other debris mixed in the material move to the edge of the grinding plate with the material, they cannot be blown up by the wind due to their heavy weight. They fall to the lower chamber of the mill and are scraped into the slag discharge port and discharged out of the machine by the scraper plate installed at the bottom of the grinding plate.

Mineral Ore Vertical Grinding Mill Technical Parameters | |||||||||||

Model | Inner Diameter Of Ring(mm) | Max Input Size(mm) | Output Size | Inlet Air Temperature(℃) | Outlet Air Temperature(℃) | Best Input Moisture | Input Moisture needs Drying | Power Moisture After Drying | Capacity(t/h) | Main Mill Motor(kw) | |

μm | mesh | ||||||||||

SRM1300 | 1300 | ≤30 | 212-45 | 70-325 | ≤350 | 70-95 | ≤4% | 4%-15% | ≤1% | 10-35 | 132-200 |

SRM1300 | 1500 | ≤40 | 212-45 | 70-325 | ≤350 | 70-95 | ≤4% | 4%-15% | ≤1% | 13-48 | 220-285 |

SRM1300 | 1700 | ≤50 | 212-45 | 70-325 | ≤350 | 70-95 | ≤4% | 4%-15% | ≤1% | 18-68 | 315-400 |

SRM1300 | 1900 | ≤60 | 212-45 | 70-325 | ≤350 | 70-95 | ≤4% | 4%-15% | ≤1% | 23-85 | 450-600 |

SRM1300 | 2200 | ≤70 | 212-45 | 70-325 | ≤350 | 70-95 | ≤4% | 4%-15% | ≤1% | 36-135 | 600-750 |

Coal Powder Vertical Grinding Mill Technical Parameters | |||||||||||

Model | Inner Diameter Of Ring(mm) | Max Input Size(mm) | Raw Coal Grindability Index(HGI) | Coal Output Size | Inlet Air Temperature(℃) | Outlet Air Temperature(℃) | Best Input Moisture | Input Moisture needs Drying | Coal Power Moisture | Capacity(t/h) | Main Mill Motor(kw) |

SRM1300 | 1300 | ≤30 | ≤55 | ≤15% | ≤350 | 70-95 | ≤4% | 4%-15% | ≤1% | 10-18 | 132-200 |

SRM1300 | 1500 | ≤40 | ≤55 | ≤15% | <350 | 70-95 | ≤4% | 4%-15% | ≤1% | 13-25 | 220-285 |

SRM1300 | 1700 | ≤50 | ≤55 | ≤15% | ≤350 | 70-99 | ≤4% | 4%-15% | ≤1% | 18-32 | 315-400 |

SRM1900 | 1900 | ≤60 | ≤55 | ≤15% | ≤350 | 70-95 | ≤4% | 4%-15% | ≤1% | 23-40 | 450-600 |

SRM2000 | 2200 | ≤70 | ≤55 | ≤15% | ≤350 | 70-95 | ≤4% | 4%-15% | ≤1% | 36-54 | 600-750 |