Hydraulic roller crusher machine is a model extended from the spring roller machine. The advantage of the hydraulic structure is that it can accurately control the pressure between the rollers. Long-term continuous operation can still ensure the crushing pressure between the two rollers. Therefore, equipping a roller counter in the grinding system can fully utilize the production capacity of the grinding equipment. Generally, the output can be increased by 30% - 40%, and the total energy consumption can be reduced by 20% to 30%.

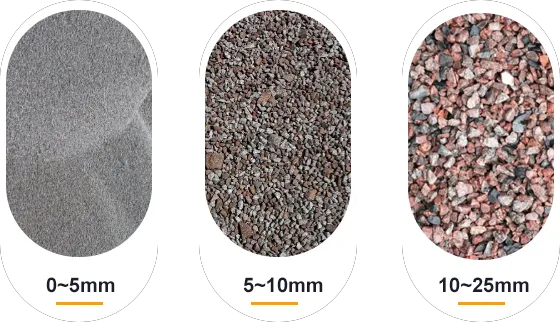

Hydraulic Roller Crusher has the advantages of good particle shape, high yield, strong adaptability, low energy consumption, and easy maintenance in terms of sand-making effect. It has an indispensable position in the entire sand and gravel production line. The roller crusher machine sand can not only reduce the dependence on natural sand. Still, it can also use resources such as river pebbles to achieve resource recycling, which has good economic and environmental benefits.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

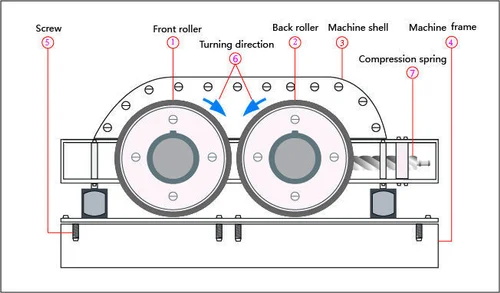

Hydraulic double-roller sand-making machine mainly uses a triangle belt or universal joint coupling to transmit and adjust the gap between the rollers. It uses a hydraulic cylinder to control the pressure of the rollers and uses the two rollers to squeeze the material for crushing. The material falls between the two rollers through the feeding port. The finished product naturally falls after being pressed and crushed by the rollers. When encountering extremely hard or unbreakable materials, the rollers can automatically retreat by the action of the hydraulic cylinder so that the gap between the two rollers is reduced. The gap becomes more extensive, and the hard or unbreakable materials naturally fall to ensure the machine is not damaged. There is a particular gap between the two oppositely rotating rollers. By changing the gap, the discharge granularity of the product can be controlled.

The working principle of the roller crusher is to use the relative rotation between two pairs of rollers to squeeze and crush the raw materials, producing shearing and crushing effects. The required sand and gravel aggregates finally form after the rollers rotate the raw materials at high speed.

Model | Roll Diameter(mm) | Roll Width(mm) | Feeding Size(mm) | Capacity(t/h) | Power(kW) |

2PGY750X500 | φ750 | 500 | ≤40 | 20-30 | 2×(22-30) |

2PGY800X600 | φ800 | 600 | ≤40 | 30-40 | 2×(30-37) |

2PGY800X800 | φ800 | 800 | ≤40 | 40-50 | 2×(37-45) |

2PGY1000x800 | φ1000 | 800 | ≤40 | 50-80 | 2×(45-55) |

2PGY1000x1000 | φ1000 | 1000 | ≤40 | 80-100 | 2×(55-90) |

2PGY1200x1000 | φ1200 | 1000 | ≤60 | 100-120 | 2×(75-132) |

2PGY1200x1200 | φ1200 | 1200 | ≤60 | 120-150 | 2×(90-132) |

2PGY1500x1000 | φ1500 | 1000 | ≤80 | 150-200 | 2×(132-160) |

2PGY1800x1000 | φ1800 | 1000 | ≤100 | 250-300 | 2×(250-315) |

2PGY2000x1200 | φ2000 | 1200 | ≤120 | 300-400 | 2×(315-355) |