Rod mill is an important grinding equipment mainly used for grinding ore. Rod mills are available in dry and wet types, and users can choose according to their actual situation. The company adopts advanced controllable feeding and discharging technology. According to the actual grinding materials, suitable grinding bodies should be used, and the traditional point contact should be changed to line contact so that the discharge particle size is more uniform and the output is higher. It is widely used in grinding operations with relatively high requirements for the uniformity of the finished product after grinding in industries such as refractory materials, chemicals, metallurgy, and glass. In recent years, it has also been used in the sand-making industry to build sand.

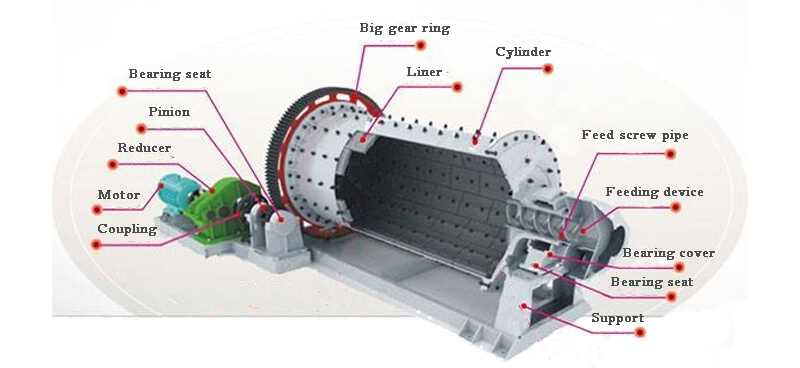

1. Cylinder Part

- The cylinder is the main working part of the rod mill and is generally welded with high-quality steel plates. Its thickness and material are determined according to the specifications of the mill, the nature of the processed materials, and the working intensity to ensure that the cylinder has sufficient strength and rigidity to withstand the weight of the grinding rods and materials and the impact force during the grinding process.

- The inner wall of the cylinder is usually lined with a wear-resistant lining, and the lining material has a variety of options such as rubber and high manganese steel. The rubber lining has good wear resistance, shock absorption and low noise. In contrast, the high manganese steel lining has higher hardness and wear resistance and is suitable for processing materials with higher hardness.

2. Grinding Rod

- The grinding rod is the key grinding medium of the rod mill and is generally made of high carbon steel or alloy steel. Its diameter and length are determined according to the cylinder size and processing requirements of the rod mill. The quality of the grinding rod directly affects the grinding effect. High-quality grinding rods have higher hardness, toughness and wear resistance and can maintain good shape and performance during long-term grinding operations.

3. Main Bearing and Transmission Device

- The main bearing is used to support the weight of the cylinder and ensure its smooth rotation. Generally, sliding bearings or rolling bearings are used. Rolling bearings have the advantages of a small friction coefficient and easy starting, while sliding bearings have the characteristics of strong load-bearing capacity.

- The transmission device mainly includes components such as the motor, reducer and coupling. The motor provides power, the reducer reduces the speed and increases the torque, and the coupling transmits the power of the motor and reducer to the cylinder so that the cylinder can rotate at a suitable speed.

1. Product Particle Size Advantage

- It can produce products with coarse particle size and uniform particle size distribution. This is because the line contact mode of the grinding rod makes the material subject to more uniform grinding and extrusion, reducing the phenomenon of over-crushing.

2. Grinding Medium Advantage

- Compared with the grinding balls of the ball mill, the movement of the grinding rod in the cylinder is more orderly, the grinding effect of the material is more selective, and the particle size range of the product can be better controlled.

3. Applicable Material Advantages

- For some materials with higher hardness, such as quartz stone, iron ore, etc., rod mills can effectively grind, and due to its grinding method, it can reduce the wear of the grinding medium (grinding rods) and extend the service life of the equipment.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

The working principle of a rod mill is similar to that of a ball mill, but the grinding medium is different. It uses a low-speed rotating cylinder to drive the internal grinding rods to move. When the cylinder rotates, the grinding rods are brought to a certain height and then fall under the action of centrifugal force and friction. The movement mode of these grinding rods in the cylinder is mainly cascading; that is, the rods are in line contact with each other to grind the material.

During the grinding process, the material enters the cylinder from the feed port of the mill. As the cylinder rotates, the grinding rods continuously crush and grind the material. Due to the line contact mode of the grinding rods, the material is mainly subjected to extrusion and grinding, which can effectively avoid excessive crushing and is more suitable for producing products with coarse particle size and uniform particle size distribution.

Rod Mill Technical Parameters | ||||||||

Model | Specifications(mm) | Rotary Speed | Input Size(mm) | Output Size(mm) | Capacity | Power | Weight(t) | |

Diameter | Length | |||||||

MBS0918 | 900 | 1800 | 36-38 | ≤25 | 0.833-0.147 | 0.62-3.2 | 18.5 | 5.9 |

MBS0924 | 900 | 2400 | 36 | ≤25 | 0.833-0.147 | 0.81-4.3 | 22 | 6.7 |

MBS1224 | 1200 | 2400 | 36 | ≤25 | 0.833-0.147 | 1.1-4.9 | 30 | 13.9 |

MBS1530 | 1500 | 3000 | 29.7 | ≤25 | 0.833-0.147 | 2.4-7.5 | 75 | 19.8 |

MBS1830 | 1830 | 3000 | 25.4 | ≤25 | 0.833-0.147 | 4.8-11.6 | 130 | 34.9 |

MBS2130 | 2100 | 3000 | 23.7 | ≤25 | 0.833-0.147 | 14-35 | 155 | 46.5 |

MBS2136 | 2100 | 3600 | 23.7 | ≤25 | 0.833-0.147 | 19-43 | 180 | 48.7 |

MBS2430 | 2400 | 3000 | 21 | ≤50 | 0.833-0.147 | 25-65 | 245 | 59.7 |

MBS2736 | 2700 | 3600 | 20.7 | ≤50 | 0.833-0.147 | 32-86 | 380 | 92.5 |

MBS2740 | 2700 | 4000 | 20.7 | ≤50 | 0.833-0.147 | 32-92 | 400 | 95 |

MBS3245 | 3200 | 4500 | 18 | s50 | 0.833-0.147 | 64-180 | 630 | 149 |