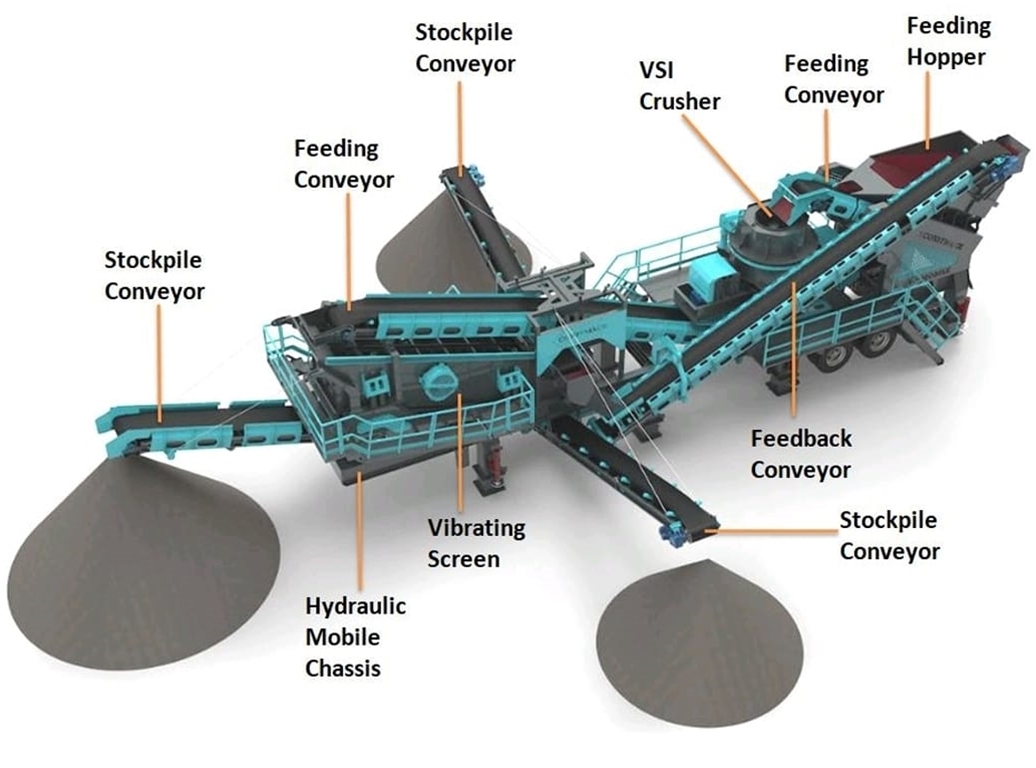

Wheeled Mobile VSI Sand Making Plant (mobile crushing plant) is also called a mobile sand making machine or a mobile sand maker. Mobile VSI crusher has a high chassis and a small turning radius, which is convenient for driving on ordinary roads and even more convenient for driving in the rugged and harsh road environment of the crushing site: it saves time for quick entry into the construction site.

Mobile VSI Sand Making Plant is conducive to entering a reasonable construction area, eliminating the cumbersome steel frame structure and foundation construction during crushing, saving a lot of time. According to the customer's requirements for material types and products in the process, a more flexible process solution configuration can be provided to meet the user's various requirements, such as mobile crushing and mobile screening, making the production organization and logistics transfer more direct and effective.

Mobile VSI Sand Making Plant has strong mobility and provides a more flexible working space.

Mobile VSI Sand Making Plant reduces the cost of material transportation, crushes the material on site, and saves energy.

Mobile VSI Sand Making Plant operates directly and effectively, can be used independently, and offers a variety of process solution configurations.

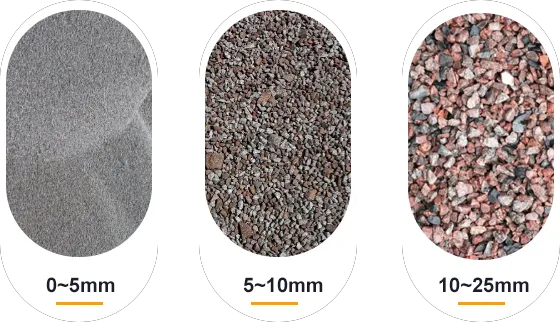

Different crushing and screening systems can be formed according to needs to meet various crushing needs.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

The working principle of the Mobile VSI Sand Making Plant is the same as that of the Vertical Shaft Impact Sand Making Machine. The material enters the sand making machine from the feed hopper and is divided into two parts by the distributor. One part enters the high-speed rotating impeller from the middle of the distributor and is rapidly accelerated in the impeller. Its acceleration can reach hundreds of times the acceleration of gravity. Then, it is ejected from the three evenly distributed flow channels of the impeller at a speed of 60-70 m/s. First, it is impacted and crushed by a part of the material that falls from the distributor's surroundings. Then, it impacts the material lining in the vortex branch cavity together, is rebounded by the material lining, and impacts obliquely upward to the top of the vortex cavity. Then, it changes its direction of movement and deflects downward. The material emitted from the impeller flow channel forms a continuous material curtain. In this way, a piece of material is subjected to two or more collisions, friction grinding, and crushing in the vortex crushing cavity. The crushed material is discharged from the lower discharge port. It forms a closed circuit with the circulating screening system. Generally, three cycles can crush the material into less than 20 mesh.

During the whole crushing process, the materials impact and crush each other without direct contact with metal components but impact and rub against the material lining to crush, which reduces corner pollution and prolongs the mechanical wear time. The ingenious airflow self-circulation inside the vortex cavity eliminates dust pollution.

Mobile VSI Sand Making Plant Technical Parameters | |||||

Standard Model | Corollary Equipment | Corollary Equipment | Overall Dimension (mm) | ||

Model | Feeding Size (mm) | Capacity (t/h) | |||

S-V7611 | 3YZK1548 | VSI7611 | 35 | 120-180 | 12500 x 2600 x 4300 |

S-V8518 | 3YZK1848 | VSI8518 | 40 | 200-260 | 14200 x 3000 x 4500 |

S-V9526 | 3YZK1860 | VSI9526 | 45 | 300-380 | 14500 x 3000 x 4500 |

S-V1140 | 3YZK2160 | 5X1140 | 50 | 450-520 | 15500 x 3100 x 4500 |

S-5V7615 | 3YZK1548 | 5X7615 | 35 | 150-280 | 12500 x 2600 x 4300 |

S-5V8522 | 3YZK1848 | 5X8522 | 40 | 240-380 | 14200 x 3000 x 4500 |

S-5V9532 | 3YZK1860 | 5X9532 | 45 | 350-540 | 14500 x 3000 x 4500 |

S-5V1145 | 3YZK2160 | 5X1145 | 50 | 500-640 | 15500 x 3100 x 4500 |

S-5V1150 | 3YZK2260 | 5X1150 | 50 | 550-750 | 15800 x 3200 x 4500 |