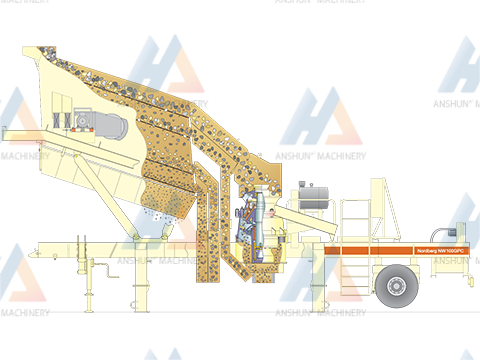

Mobile Cone Crusher Plant has reliable performance and convenient maintenance. Mobile Cone Crusher is equipped with a high-performance cone crusher, high crushing efficiency, versatility, excellent crushing product quality, and has a light and reasonable structural design. Reliable and stable quality assurance meets the requirements of coarse, medium and fine material crushing and screening. It has established a good quality reputation for new and old customers at home and abroad.

The mobile cone crusher adopts a new modular design concept. Multiple models share a common frame, which allows for easy interchange between different host systems of the same model. Different production needs can be easily met only by replacing the host system. The diversified design is more worry-free.

The mobile cone crusher equipment space system configuration is complete. It can work alone in one stage of crushing. It can also work together with multiple equipment, such as a mobile jaw crusher and mobile sand-making machine, to meet the needs of multiple crushing and screening combinations.

The mobile cone crusher plant includes seven modules and 24 models. It is fully combined. The output, input, output, etc., can all be selected according to the host cone crusher. Customizing personalized solutions highlights the humanized design.

The mobile cone crusher has a flexible parking system, which can quickly enter the working mode. At the same time, it can control the equipment feeding and discharging, conveyor belt folding and other actions through the hydraulic system. The PLC intelligent operating system is safe, reliable, and easy to operate.

The mobile cone crusher has added water spray dust suppression devices, iron removal devices, silencers, etc., which can meet environmental protection standards without pressure. It adopts an oil-electric hybrid operation, energy and fuel saving, and multiple energy supply methods. Users have more freedom to choose, and the equipment is more efficient.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

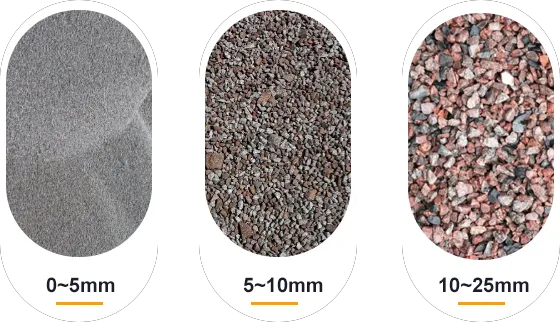

The working principle of the mobile cone crusher is that the material is evenly transported to the cone crusher by the feeder. After the cone crusher is initially crushed, a closed-circuit system is formed through the circular vibrating screen to realize the cyclic crushing of the material. The finished material is output by the conveyor for continuous crushing. The wheeled mobile cone crusher + mobile vibrating screen plant can remove the circular vibrating screen according to the actual production needs to realize the direct initial crushing of the material. It is convenient and flexible to use with other crushing equipment.

Mobile Cone Crusher Plant Technical Parameters | |||||

Standard Model | Corollary Equipment | Corollary Equipment | Overall Dimension (mm) | ||

Model | Feeding Size (mm) | Capacity (t/h) | |||

S-CS75 | 3YZK1848 | CS75 | ≤160 | 59-163 | 12600×2800×4400 |

S-CS110 | 3YZK1860 | CS110 | ≤178 | 100-200 | 13800×3000×4400 |

S-CS160 | 3YZK2160 | CS160 | ≤188 | 132-253 | 13800×3000×4400 |

S-CS220 | 3YZK2160 | CS220 | ≤230 | 215-330 | 14500×3000×4500 |

S-H420 | 3YZK1848 | SH420 | ≤240 | 85-170 | 12600×2900×4400 |

S-H430 | 3YZK1860 | SH430 | ≤360 | 120-345 | 13800×3000×4500 |

S-H440 | 3YZK2260 | SH450 | ≤450 | 255-605 | 14800×3200×4600 |

S-HP200 | 3YZK2160 | SHP200 | ≤185 | 145-250 | 14200×3000×4500 |

S-HP300 | 3YZK2260 | SHP300 | ≤230 | 180-300 | 16500×3200×4600 |

S-HP400 | 3YZK2260 | SHP400 | ≤230 | 220-380 | 16500×3200×4600 |