PE jaw crusher is the most commonly used coarse crushing equipment among the two major series of jaw crushers. This equipment adopts mature crushing technology, and its performance and structure adopt a systematic and comprehensive optimized design. It has high strength, reliability, durability, and crushing force. It has the characteristics of large size and high production output. It is often used as a primary crusher in various stone and ore-crushing production lines.

Stable & Reliable Performance

It is made of high-quality steel castings. At the same time, compared with other crushers of the same specifications, we use larger and more durable eccentric shaft bearings to give it a higher load-bearing capacity and make the equipment operation more stable and reliable.

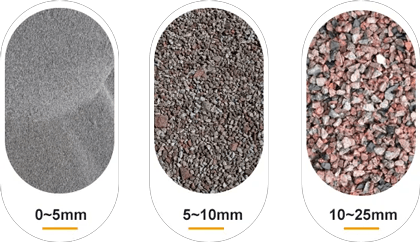

Finished Product Has a Good Grain Shape

The PE jaw crusher adopts the driving extrusion crushing principle, which significantly reduces the proportion of cubes in the product, reduces the content of needle-shaped products, and makes the particle size more uniform.

Long Lasting

It is made of high-hardness, wear-resistant materials, greatly enhancing its pressure and wear resistance and extending the machine's service life.

Simple Structure and Easy To Operate

After continuous optimization, the machine structure is also continuously upgraded and optimized. The structure is simple and easy to operate, maintenance is more convenient, and downtime for maintenance is greatly shortened.

Good Dustproof Effect

It is equipped with a dust bag device. When dust enters the filter bag, the dust bag expands rapidly in an instant and shakes off the dust with the reverse action of the airflow.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

The motor drives the belt and pulley, moving the movable jaw up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thus pushing the movable jaw plate closer to the fixed jaw plate, and at the same time, the material is squeezed. To achieve the purpose of crushing, when the movable jaw moves downward, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring. At this time, the crushed material is discharged from the lower opening of the crushing cavity. As the motor rotates, the crusher's movable jaw makes periodic movements to crush and discharge materials, realizing mass production.

Model | Size of Feed Opening(mm) | Max.feed Size(mm) | Discharge Opening Adjustment Range(mm) | Processing Capacity(t/h) | Power(kW) | Overall Dimension LxWxH(mm) |

PE400×600 | 400×600 | 350 | 40-90 | 15-60 | 30 | 1650×1588×1050 |

PE500×750 | 500×750 | 425 | 50-100 | 40-110 | 55 | 1956×1918×1920 |

PE600×900 | 600×900 | 500 | 60-125 | 90-180 | 75 | 2250×2733×2280 |

PE750×1060 | 750×1060 | 630 | 60-150 | 110-380 | 110 | 2531×2455×2783 |

PE900×1060 | 900×1060 | 700 | 100-160 | 180-380 | 110 | 2900×2657×2950 |

PE900×1200 | 900×1200 | 750 | 110-165 | 220-450 | 110-132 | 3100×2760×3260 |

PE1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 132-160 | 3480×2876×3330 |

PE1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 160-220 | 4200×3300×3500 |

PEX250×750 | 250×750 | 210 | 15-50 | 15-30 | 22-30 | 1400×1751×1515 |

PEX350×750 | 350×750 | 300 | 15-50 | 18-40 | 30 | 1485×1680×1648 |

PEX250×1000 | 250×1000 | 210 | 15-60 | 15-60 | 30 | 1550×1964×1380 |

PEX250×1200 | 250×1200 | 210 | 25-60 | 20-60 | 37-45 | 1530×1946×1380 |

PEX300×1300 | 300×1300 | 250 | 20-90 | 35-70 | 55-75 | 2000×2320×1730 |

PEX500×1500 | 500×1500 | 400 | 40-110 | 45-150 | 75 | 2850×2640×2100 |